close

L

O

A

D

I

N

G

- Open Hours: Mon-Fri 8:00 am-6:00 pm

- Email: ewastestar@gmail.com

- Address: 6A Anvil Way, Welshpool WA 6109, Australia

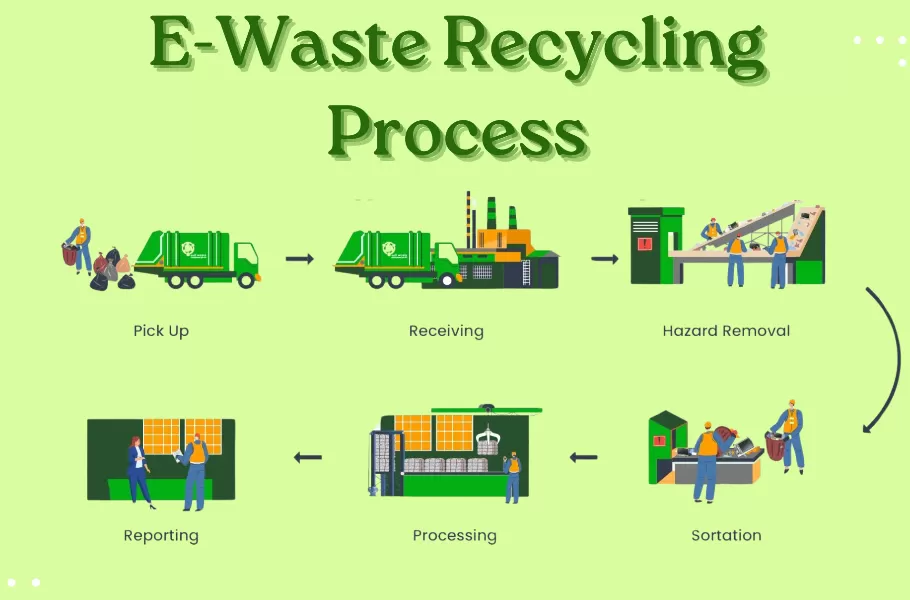

Process of E-Waste Recycling: Step-by-Step Breakdown